Do you believe that this item violates a copyright? A wooden base provides the bench mounting surface, while an L-shaped set of handles attached with a rectangular hollow section gives a comfortable grip to pull against. These will be placed between the hinges with a gap of 1/4 from both hinges. See image below for example. Signup for TwoFeetFirst's newsletter to recieve emails packed full of DIY home ideas and inspiration. Learn more, Build A Sheet Metal Brake With No Welding Required. All you need is to be able to read diagrams. It will be placed on the metal piece that is secured to the longer board.

Do you believe that this item violates a copyright? A wooden base provides the bench mounting surface, while an L-shaped set of handles attached with a rectangular hollow section gives a comfortable grip to pull against. These will be placed between the hinges with a gap of 1/4 from both hinges. See image below for example. Signup for TwoFeetFirst's newsletter to recieve emails packed full of DIY home ideas and inspiration. Learn more, Build A Sheet Metal Brake With No Welding Required. All you need is to be able to read diagrams. It will be placed on the metal piece that is secured to the longer board.  Is packed full of tips and breaks down what you need to know when you buy your next power tool. One of the tools that made these projects possible was my DIY metal brake.

Is packed full of tips and breaks down what you need to know when you buy your next power tool. One of the tools that made these projects possible was my DIY metal brake.

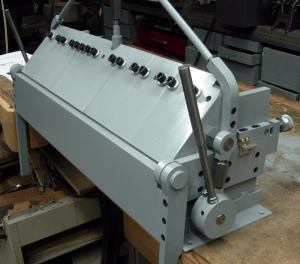

This is a cheap and simple sheet metal brake that will total cost $49 only! These videos will help you understand the steps below. Dont Spend The Goldmine And Dont Get The Shaft: The Borgeson G-Body, F-Body, S10 Steering Shaft Upgrade Is Worth Every Penny. I would use 3/16 flat metal (I used 1/8 in my brake and the top plate has bowed slightly after multiple uses). So if you're up to the task, and have some skills, this one should be worth your time. This tool will help you bend your metal sheets much easier than when using those really heavy clamps that, most of the time, can end up doing more harm than good. By clicking on the above button, you agree to Amazon's, Build Your Own Metal Working Shop From Scrap, The Metal Shaper (Build Your Own Metal Working Shop From Scrap Serie Book 3), The Dividing Head & Deluxe Accessories (Build Your Own Metal Working Shop From Scrap Serie Book 6), Previous page of related Sponsored Products. Anyone can start a successful blog, so why cant I (or you, too!)? The brake is mostly made with scrap materials and shouldn't cost more than $20 in total. TIP: Use clamps to hold the metal in place while cutting. Even the folks we know that build cars for a living, and have a sheet metal brake, rarely use them for pieces more than 18 inches long. Additional gift options are available when buying one eBook at a time. The purpose of this instructable is to create a homemade sheet metal brake that will bend up to about 3 feet long. Make a cheap and simple metal brake yourself. You are now going to attach the two 12.5 flat metal pieces to the boards. Would You Be Brave Enough To Drag Race A Suicide-Shifted Chopper Down The Strip? Then, using the hacksaw again, cut the 3/8 steel round rod to these measurements: 8 and 8. The creator used wood and angle iron. There was a problem loading your book clubs. Good ideas for making machines with simple and available materials.

This is a cheap and simple sheet metal brake that will total cost $49 only! These videos will help you understand the steps below. Dont Spend The Goldmine And Dont Get The Shaft: The Borgeson G-Body, F-Body, S10 Steering Shaft Upgrade Is Worth Every Penny. I would use 3/16 flat metal (I used 1/8 in my brake and the top plate has bowed slightly after multiple uses). So if you're up to the task, and have some skills, this one should be worth your time. This tool will help you bend your metal sheets much easier than when using those really heavy clamps that, most of the time, can end up doing more harm than good. By clicking on the above button, you agree to Amazon's, Build Your Own Metal Working Shop From Scrap, The Metal Shaper (Build Your Own Metal Working Shop From Scrap Serie Book 3), The Dividing Head & Deluxe Accessories (Build Your Own Metal Working Shop From Scrap Serie Book 6), Previous page of related Sponsored Products. Anyone can start a successful blog, so why cant I (or you, too!)? The brake is mostly made with scrap materials and shouldn't cost more than $20 in total. TIP: Use clamps to hold the metal in place while cutting. Even the folks we know that build cars for a living, and have a sheet metal brake, rarely use them for pieces more than 18 inches long. Additional gift options are available when buying one eBook at a time. The purpose of this instructable is to create a homemade sheet metal brake that will bend up to about 3 feet long. Make a cheap and simple metal brake yourself. You are now going to attach the two 12.5 flat metal pieces to the boards. Would You Be Brave Enough To Drag Race A Suicide-Shifted Chopper Down The Strip? Then, using the hacksaw again, cut the 3/8 steel round rod to these measurements: 8 and 8. The creator used wood and angle iron. There was a problem loading your book clubs. Good ideas for making machines with simple and available materials.  The cost is just $30 and it's less time-consuming. First, I am assuming you are a beginner, having only a drill, wood cutting saw, two wood clamps, and none of the specialized tools needed to work with metal.

The cost is just $30 and it's less time-consuming. First, I am assuming you are a beginner, having only a drill, wood cutting saw, two wood clamps, and none of the specialized tools needed to work with metal.  All before the Intern0t. Then, use the 3/4 spade bit for under the board. The Charcoal Foundry (Build Your Own Metal Working Shop From Scrap Serie Book 1). From PLANS out of a MAGAZINE called Popular Mechanics. This One Is Super Cool. With a few pieces of scrap wood, you are set to make the perfect metal brake for all your bending needs! This is my second time purchasing this book, I started on the brake some time ago and then it got put on the back burner for about a year.

All before the Intern0t. Then, use the 3/4 spade bit for under the board. The Charcoal Foundry (Build Your Own Metal Working Shop From Scrap Serie Book 1). From PLANS out of a MAGAZINE called Popular Mechanics. This One Is Super Cool. With a few pieces of scrap wood, you are set to make the perfect metal brake for all your bending needs! This is my second time purchasing this book, I started on the brake some time ago and then it got put on the back burner for about a year.  I would recommend making this metal brake if you are just starting out and not planning to bend tons of metal, just some brackets here and there for small projects. Learn more about me. This brake costs next to nothing to build, it's easy to build, and it is very effective because we designed it with performance in mind. By using our website and services, you expressly agree to the placement of our performance, functionality and advertising cookies. Drag Racing Valhalla Video: Mind-Blowing 1960s Footage From Maple Grove, Cecil County, Atco, and York, Featuring Every Hero! If you want something more versatile and heavy-duty, make your brake like the two tutorials linked above. The Milling Machine (Build Your Own Metal Working Shop From Scrap Serie Book 4), The Drill Press (Build Your Own Metal Working Shop From Scrap Serie Book 5). And if youre ready to get started, try making these metal farmhouse brackets. This way, you can take it easy and learn how to use the machine only when needed. To calculate the overall star rating and percentage breakdown by star, we dont use a simple average. BOLT ONS OR BOOST? Rather than welding tabs to prevent tilting I woul fasten the angle to a piece of 61 hatdwood which I would clamp to the bench. It is a device used to help hold books and other items in place when you are putting them on a shelf or behind a cabinet. Making a simple metal brake takes only ten minutes and using it is easy. The metal will be attached at the edge of each board. But because Im a beginner and do not have fancy saws to cut metal, I made my metal brake even simpler. I also used a piece of wood to steady the metal brake. All the metal brakes on this DIY guide are durable, and study, whether the wood was used or not, it depends on which you feel is easier to make and budget-friendly. Use all appropriate and proper safety precautions when attempting projects. Learn more. Although, there is a link in the description that will take you to where you can get the tools and materials you need. The top plate is your last flat metal piece (11) that will sit on top of one of the previously installed metal pieces. Please try again. TIP: If you are measuring and marking, mark in at least three spots (ends and middle). Even though its sometimes a bit tedious, bending metal sheets is something that you need to know how to do. This was made with simple angle iron and some hinges. Well here is a standard metal brake made by a creator who spent $217 to make it from scratch. It's inexpensive and works with almost any kind of steel. Full content visible, double tap to read brief content. : The making process is pretty easy to follow. Its best to find one that has a user manual and basic operating instructions.

I would recommend making this metal brake if you are just starting out and not planning to bend tons of metal, just some brackets here and there for small projects. Learn more about me. This brake costs next to nothing to build, it's easy to build, and it is very effective because we designed it with performance in mind. By using our website and services, you expressly agree to the placement of our performance, functionality and advertising cookies. Drag Racing Valhalla Video: Mind-Blowing 1960s Footage From Maple Grove, Cecil County, Atco, and York, Featuring Every Hero! If you want something more versatile and heavy-duty, make your brake like the two tutorials linked above. The Milling Machine (Build Your Own Metal Working Shop From Scrap Serie Book 4), The Drill Press (Build Your Own Metal Working Shop From Scrap Serie Book 5). And if youre ready to get started, try making these metal farmhouse brackets. This way, you can take it easy and learn how to use the machine only when needed. To calculate the overall star rating and percentage breakdown by star, we dont use a simple average. BOLT ONS OR BOOST? Rather than welding tabs to prevent tilting I woul fasten the angle to a piece of 61 hatdwood which I would clamp to the bench. It is a device used to help hold books and other items in place when you are putting them on a shelf or behind a cabinet. Making a simple metal brake takes only ten minutes and using it is easy. The metal will be attached at the edge of each board. But because Im a beginner and do not have fancy saws to cut metal, I made my metal brake even simpler. I also used a piece of wood to steady the metal brake. All the metal brakes on this DIY guide are durable, and study, whether the wood was used or not, it depends on which you feel is easier to make and budget-friendly. Use all appropriate and proper safety precautions when attempting projects. Learn more. Although, there is a link in the description that will take you to where you can get the tools and materials you need. The top plate is your last flat metal piece (11) that will sit on top of one of the previously installed metal pieces. Please try again. TIP: If you are measuring and marking, mark in at least three spots (ends and middle). Even though its sometimes a bit tedious, bending metal sheets is something that you need to know how to do. This was made with simple angle iron and some hinges. Well here is a standard metal brake made by a creator who spent $217 to make it from scratch. It's inexpensive and works with almost any kind of steel. Full content visible, double tap to read brief content. : The making process is pretty easy to follow. Its best to find one that has a user manual and basic operating instructions.  Please try again. Learn more. Other than that everything turned out great.

Please try again. Learn more. Other than that everything turned out great.  If you have made or bought a metal brake before with C-clamps and vise grips, here is a guide that will teach you how to modify that brake without using only inserting materials like a knob, knob screws, coil springs, and lots more. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. It is a way for this site to earn advertising commissions by advertising or linking to certain products and/or services, click here to read my full disclosure policy.

If you have made or bought a metal brake before with C-clamps and vise grips, here is a guide that will teach you how to modify that brake without using only inserting materials like a knob, knob screws, coil springs, and lots more. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. It is a way for this site to earn advertising commissions by advertising or linking to certain products and/or services, click here to read my full disclosure policy.  We use cookies to ensure that we give you the best experience on our website. Criminal Cyber Coin between nation states? This project doesn't require welding so it's super easy and simple to follow. Download the free Kindle app and start reading Kindle books instantly on your smartphone, tablet, or computer - no Kindle device required. : Will I build this break? i once built one of these out of a couple pine two by fours and some wishful thinking (in place of hinges), to fold a bit of flashing to go under a door. Weve seen a lot of homemade, and cheap, sheet metal brakes. You'll need wood, a flat sheet bar, carriage bolts, hinges, wing nuts, and lots more. Use a 3/8 wood drill bit to drill two holes 1-1/2 deep. Maybe you already have some metal in your garage but you dont have a way to bend them. We are always looking for good bang shifty stories, projects, photos & videos. Hey there, Im Megan! , Screen Reader All you need to do is drill 3/8 holes on the 2 side of the smaller wood board. This One Is Super Cool.

We use cookies to ensure that we give you the best experience on our website. Criminal Cyber Coin between nation states? This project doesn't require welding so it's super easy and simple to follow. Download the free Kindle app and start reading Kindle books instantly on your smartphone, tablet, or computer - no Kindle device required. : Will I build this break? i once built one of these out of a couple pine two by fours and some wishful thinking (in place of hinges), to fold a bit of flashing to go under a door. Weve seen a lot of homemade, and cheap, sheet metal brakes. You'll need wood, a flat sheet bar, carriage bolts, hinges, wing nuts, and lots more. Use a 3/8 wood drill bit to drill two holes 1-1/2 deep. Maybe you already have some metal in your garage but you dont have a way to bend them. We are always looking for good bang shifty stories, projects, photos & videos. Hey there, Im Megan! , Screen Reader All you need to do is drill 3/8 holes on the 2 side of the smaller wood board. This One Is Super Cool.  Richard Hogben liked Mk2 ATtiny | AVR Programmer Shield. TIP: Use a shop-vac while drilling to help with the cleanup. Cut the 1-1/2 metal bar to these measurements: 12.5, 12.5, and 11 using the hacksaw. : the problem i had was worse than that without hinges, i had a heck of a time bending the whole length in one consistent go, so the metal became a little rippled. It also analyzed reviews to verify trustworthiness. Go make your own bending machine. Try this DIY 8-foot sheet metal brake that will be a helpful tool, that you can make in your home workshop and garage. TIP: After cutting one piece, use the metal file to smooth out the metal edges so they are not sharp. The Sheet Metal Brake is also known as book 7 from the best selling 7 book series, 'Build Your Own Metal Working Shop From Scrap'. You can bend thinner metal, it just won't be as sharp a bend, for thicker you have to have a new clamp leaf. This item has a maximum order quantity limit. So why not build a DIY Sheet Metal Brakelike this for yourself?

Richard Hogben liked Mk2 ATtiny | AVR Programmer Shield. TIP: Use a shop-vac while drilling to help with the cleanup. Cut the 1-1/2 metal bar to these measurements: 12.5, 12.5, and 11 using the hacksaw. : the problem i had was worse than that without hinges, i had a heck of a time bending the whole length in one consistent go, so the metal became a little rippled. It also analyzed reviews to verify trustworthiness. Go make your own bending machine. Try this DIY 8-foot sheet metal brake that will be a helpful tool, that you can make in your home workshop and garage. TIP: After cutting one piece, use the metal file to smooth out the metal edges so they are not sharp. The Sheet Metal Brake is also known as book 7 from the best selling 7 book series, 'Build Your Own Metal Working Shop From Scrap'. You can bend thinner metal, it just won't be as sharp a bend, for thicker you have to have a new clamp leaf. This item has a maximum order quantity limit. So why not build a DIY Sheet Metal Brakelike this for yourself?  Forever!

Forever!  The link is in the description of this video. All projects are attempted at the readers own risk. Also, file the ends to remove the sharp edges. The creator made his metal brake and had some other extra guide in the description so that you can have many options to choose from, in case you don't like his method. With the help of this video guide, youll learn everything about building your own metal brake. The book arrived in Brand New Condition. Help others learn more about this product by uploading a video!

The link is in the description of this video. All projects are attempted at the readers own risk. Also, file the ends to remove the sharp edges. The creator made his metal brake and had some other extra guide in the description so that you can have many options to choose from, in case you don't like his method. With the help of this video guide, youll learn everything about building your own metal brake. The book arrived in Brand New Condition. Help others learn more about this product by uploading a video!  Put this attractive dynamo in your yard, and watch it work. Reviewed in the United States on January 5, 2022. Once the metal piece is clamped and not moving, drill a 5/16 hole using the 5/16 metal drill bit through the already-drilled 5/16 hole through the bottom metal piece and wood board. This is a jig you build to do a project, accordingly it is useful to fold metal to go around a window, aka to put simple long bends in flashing. 19 DIY Battery Box Projects: How To Build A Battery Box, 14 DIY Slant Board Projects: How To Build A Slant Board, 15 DIY Simple Dimple Projects: How To Make A Simple Dimple, 14 DIY Paracord Jig Projects: How To Make A Paracord Jig, 7 Homemade Dovetail Jigs You Can DIY Easily, 23 DIY Micro Camper Plans You Can Build Easily, 25 Brilliant and Easy to Build DIY Computer Desks, 23 DIY Computer Case - How To Build A Computer Case, 15 DIY Target Stand Projects - How To Build A Target Stand For Shooting, 25 DIY Shower Wall Panels Plans You Can DIY Easily, 19 DIY Slide Projects - How To Build A Play Slide, Diy Game & Recreation Room Furniture Projects, 20 DIY Metal Brake Ideas: How To Make A Metal Sheet Brake, 15 DIY Scaffolding Ideas: Perfect For In & Outdoor Projects, 25 DIY Deer Blind Projects: Homemade Deer Hunting Blind Ideas. Unable to add item to List. I have all the Gingery "metal shop from scrap" series except the drill press, and I find these books all quite good, even if you have no plans to build one. You want these handles about the distance of your metal pieces (no more than your shoulder width) and about 1-1/2 deep. : Clamp the 11 metal piece so that it sits between the screws on the longer board and 1/8 away from the edge of the bottom metal. Hard Worker: This Nitrous Injected Small Block Makes 898hp At Less Than 7,000 RPM! So, I wish you all the best metal brake making time, bye. After the hinges are centered, mark the screw holes with a pencil. No longer is there a need to buy an expensive bend brake. ASIN , Print length The project came about simply because [Bob] needed to bend 42 sections of flashing, and couldnt find a decent deal on a sheet metal brake above 36 wide. maker wrote a reply on Internet of Things Microscope. Most folks could buy whatever they're going to make with this cheaper if their time is worth much. The steps are easy to follow. Forged in Flames (Made of Steel Series Book 2), A Whirlwind of Color (The Hunted Series Book 7).

Put this attractive dynamo in your yard, and watch it work. Reviewed in the United States on January 5, 2022. Once the metal piece is clamped and not moving, drill a 5/16 hole using the 5/16 metal drill bit through the already-drilled 5/16 hole through the bottom metal piece and wood board. This is a jig you build to do a project, accordingly it is useful to fold metal to go around a window, aka to put simple long bends in flashing. 19 DIY Battery Box Projects: How To Build A Battery Box, 14 DIY Slant Board Projects: How To Build A Slant Board, 15 DIY Simple Dimple Projects: How To Make A Simple Dimple, 14 DIY Paracord Jig Projects: How To Make A Paracord Jig, 7 Homemade Dovetail Jigs You Can DIY Easily, 23 DIY Micro Camper Plans You Can Build Easily, 25 Brilliant and Easy to Build DIY Computer Desks, 23 DIY Computer Case - How To Build A Computer Case, 15 DIY Target Stand Projects - How To Build A Target Stand For Shooting, 25 DIY Shower Wall Panels Plans You Can DIY Easily, 19 DIY Slide Projects - How To Build A Play Slide, Diy Game & Recreation Room Furniture Projects, 20 DIY Metal Brake Ideas: How To Make A Metal Sheet Brake, 15 DIY Scaffolding Ideas: Perfect For In & Outdoor Projects, 25 DIY Deer Blind Projects: Homemade Deer Hunting Blind Ideas. Unable to add item to List. I have all the Gingery "metal shop from scrap" series except the drill press, and I find these books all quite good, even if you have no plans to build one. You want these handles about the distance of your metal pieces (no more than your shoulder width) and about 1-1/2 deep. : Clamp the 11 metal piece so that it sits between the screws on the longer board and 1/8 away from the edge of the bottom metal. Hard Worker: This Nitrous Injected Small Block Makes 898hp At Less Than 7,000 RPM! So, I wish you all the best metal brake making time, bye. After the hinges are centered, mark the screw holes with a pencil. No longer is there a need to buy an expensive bend brake. ASIN , Print length The project came about simply because [Bob] needed to bend 42 sections of flashing, and couldnt find a decent deal on a sheet metal brake above 36 wide. maker wrote a reply on Internet of Things Microscope. Most folks could buy whatever they're going to make with this cheaper if their time is worth much. The steps are easy to follow. Forged in Flames (Made of Steel Series Book 2), A Whirlwind of Color (The Hunted Series Book 7).  Very little prior knowledge is needed (meaning you don't need to be a professional metal fabricator) to build a simple to use metal brake. Its a build that any experienced hacker could whip up in an afternoon and be pumping out basic sheet metal parts by sundown, and requires no welding to boot. Brake pads and rotors can be purchased separately, but spending extra money on them can get tedious quickly. Make your own DIY machine with this improved Harbor Freight Metal Bending Brake. The Cozy Wizard: FREE Heating and Cooling - Forever! Reviewed in the United States on April 10, 2015. You may need to bend metal sheets into various kinds of shapes like circular shapes for light fixtures, lettering or labeling signs, or any other shape depending on your specific needs. . The truth is that most every panel you would ever use a brake for in your hot rod or race car is going to be 24 inches maximum. Iron Trap Model A Shop Truck: Its Back Together And Better Than Ever!

Very little prior knowledge is needed (meaning you don't need to be a professional metal fabricator) to build a simple to use metal brake. Its a build that any experienced hacker could whip up in an afternoon and be pumping out basic sheet metal parts by sundown, and requires no welding to boot. Brake pads and rotors can be purchased separately, but spending extra money on them can get tedious quickly. Make your own DIY machine with this improved Harbor Freight Metal Bending Brake. The Cozy Wizard: FREE Heating and Cooling - Forever! Reviewed in the United States on April 10, 2015. You may need to bend metal sheets into various kinds of shapes like circular shapes for light fixtures, lettering or labeling signs, or any other shape depending on your specific needs. . The truth is that most every panel you would ever use a brake for in your hot rod or race car is going to be 24 inches maximum. Iron Trap Model A Shop Truck: Its Back Together And Better Than Ever!  This video guide is simple to understand and follow. Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates, Book 7 of 7: Build Your Own Metal Working Shop From Scrap, 90-Minute Craft, Hobby & Home Short Reads, Learn more how customers reviews work on Amazon.

This video guide is simple to understand and follow. Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates, Book 7 of 7: Build Your Own Metal Working Shop From Scrap, 90-Minute Craft, Hobby & Home Short Reads, Learn more how customers reviews work on Amazon.